After the diabase is broken into sand and gravel aggregate, it can be made into rubberized asphalt mixture, which has excellent high temperature resistance, low temperature resistance, and water resistance, so it is very suitable for laying highways and airport runways.

There are many crusher equipments that can be used for rock crushing, such as jaw crusher, impact crusher, cone crusher, impact crusher, compound crusher, etc. What kind of equipment should be used to crush diabase?

1. First consider the hardness of diabase raw materials

Dolerite has high Mohs hardness, above grade 6 or 7, and belongs to hard rock, so it is necessary to choose jaw crusher, cone crusher, impact crusher, etc. that can be used for hard rock crushing. If it is suitable for processing For the impact crushing and composite crushing of soft materials to process diabase, the equipment parts will wear out very quickly, and the parts may have to be replaced in half a month.

2. Secondly, consider the size of the diabase raw material and the requirements of the discharge particle size

The jaw crusher is mainly used for the coarse crushing of large pieces of diabase. If the particle size of the diabase raw material is less than 150mm, then the coarse crushing link can be omitted, and the cone crusher suitable for the second-stage crushing can be directly used for the secondary crushing treatment. The crusher can crush the diabase to about 60-5mm, and the specific particle size it can be crushed into depends mainly on the type of cone crusher used.

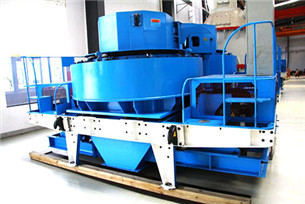

If the output smaller than 5mm is required, after the diabase is crushed from the cone, it must be crushed by the impact sand making machine, and the output fineness of the impact crusher is about 5-0mm.

3. Finally, consider the capacity of the equipment

Each type of crusher has a variety of models. Generally, the larger the model, the higher the capacity. For the selection of the capacity of the equipment, try to choose the one that is a little higher than the actual demand, so that the equipment can play a better operating effect.

Comments

Post a Comment