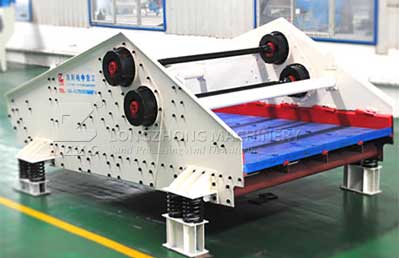

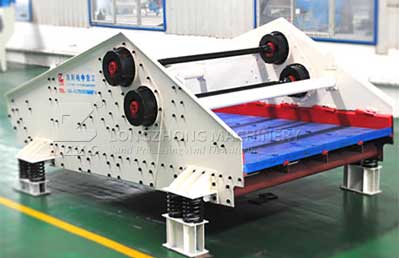

For many users who use dewatering screens, the quality of the sieve plates is very important, because the quality of the sieve plates directly affects the production volume, which reduces the economic benefits. Although it has been said that if the sieve plates are seriously damaged, replace them with a new one. However, after all, replacing the sieve plate is a very troublesome and unnecessary thing, so no one wants to continue to do so. However, in recent years, a new dewatering sieve plate appeared in the mining equipment parts market, called polyurethane dewatering sieve plate.

The sieve plate of the dewatering sieve is related to the screening effect and the dewatering effect, so the importance is self-evident, so it is necessary to choose the quality when purchasing the dewatering sieve.

1. The customer asks: How long is the service life of the sieve plate of the polyurethane dewatering sieve? How can I reduce the frequency of sieve plate replacement?

Under normal circumstances, the service life of the polyurethane dewatering sieve can be used for more than

3 months, even within 1-2 years. It is necessary to calculate the thickness of the material on the sieve surface and select the appropriate equipment model. The material layer is 50-100mm, which reduces the overload of the equipment, and the life of the sieve plate will increase, and the frequency of the sieve plate replacement can also be reduced.

2, the customer asks: What material is the sieve plate of the dewatering sieve? Wearable? What are the advantages?

Polyurethane sieve plate; the sieve plate is lined with high-strength steel plate, which has the advantages of high wear resistance; the single sieve plate has small area and low replacement cost.

3. The customer asks: Is the sieve plate of the dewatering screen easy to block? What should I do if the sieve holes are often blocked?

No blocking, the sieve plate is inverted triangle design; the sieve plate for dry discharge is dehydrated by the filter layer, which does not affect the dewatering effect. Therefore, the above is a detailed introduction of the service life of the dewatering sieve plate that most of the customers asked about. If you have any questions about the service life of the dewatering sieve, please contact Longzhong Heavy Industry. support hotline:***. You can also visit the following website for details.

https://www.lzzgmachine.com

http://www.sandmakingmachinelz.com

The sieve plate of the dewatering sieve is related to the screening effect and the dewatering effect, so the importance is self-evident, so it is necessary to choose the quality when purchasing the dewatering sieve.

1. The customer asks: How long is the service life of the sieve plate of the polyurethane dewatering sieve? How can I reduce the frequency of sieve plate replacement?

Under normal circumstances, the service life of the polyurethane dewatering sieve can be used for more than

3 months, even within 1-2 years. It is necessary to calculate the thickness of the material on the sieve surface and select the appropriate equipment model. The material layer is 50-100mm, which reduces the overload of the equipment, and the life of the sieve plate will increase, and the frequency of the sieve plate replacement can also be reduced.

2, the customer asks: What material is the sieve plate of the dewatering sieve? Wearable? What are the advantages?

Polyurethane sieve plate; the sieve plate is lined with high-strength steel plate, which has the advantages of high wear resistance; the single sieve plate has small area and low replacement cost.

3. The customer asks: Is the sieve plate of the dewatering screen easy to block? What should I do if the sieve holes are often blocked?

No blocking, the sieve plate is inverted triangle design; the sieve plate for dry discharge is dehydrated by the filter layer, which does not affect the dewatering effect. Therefore, the above is a detailed introduction of the service life of the dewatering sieve plate that most of the customers asked about. If you have any questions about the service life of the dewatering sieve, please contact Longzhong Heavy Industry. support hotline:***. You can also visit the following website for details.

https://www.lzzgmachine.com

http://www.sandmakingmachinelz.com

Comments

Post a Comment