Sand washing wastewater refers to the wastewater generated by the washing sand and gravel production enterprises in the production process. Sand and gravel is one of the basic materials of the building. With the increasing demand for domestic sand and gravel, the natural sand is facing the reduction of resources and environmental protection. The pressure, washed sand will be used as an important source of construction sand in the building materials market. Washed sand can be widely used in concrete, mortar and products. It has become a good market prospect in modern construction projects. The replacement of natural sand in quality and quantity is one of the signs that the artificial sandstone production line has entered a new era of development.

The sand washing wastewater is the water produced by sand dewatering screen. The main pollution factors are chemical oxygen demand and suspended solids, and the suspended solids content is the largest, the concentration is about 3000mg/L, forming a large amount of muddy water. The characteristics of the mud depend on its composition and are related to the local geological conditions. The general characteristic is that the mud is yellowish in appearance, uniform and sticky, and does not stratify for a long time. The specific gravity is between 1.20 and 1.46 (including the specific gravity of yellow sand). The mud content is 20% to 30%, and the pH value is 6 to 7. Before the wastewater is not comprehensively treated, it will be produced for 8 hours per day, 25 days per month, and 10 months per year. The annual production of wastewater is 80,000 tons (here is calculated by one mill). These wastewaters have about 80 tons of chemical oxygen demand (COD) and 8,000 tons of suspended solids (SS). If they do not treat their production wastewater in a timely and effective manner, they will not only waste a lot of water resources, pollute water quality, affect road traffic, and affect nearby areas. The normal production and life of residents will even intensify social conflicts and increase disharmony factors in society.

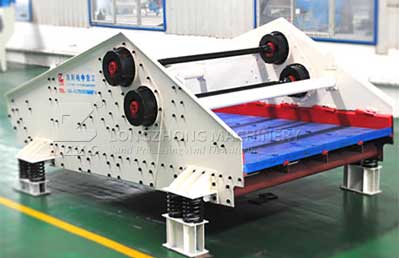

The treatment of sand washing wastewater is nothing more than the separation of mud and water, and the mud sand is separated by physical methods. Since the sand washing wastewater contains a large amount of sediment, the fine sand is first precipitated by the deep sediment purification body, and then the fine sand is precipitated. Control the solid content entering the dosing and flocculation step to achieve the purpose of reducing the cost of the drug, and then add the flocculant to form a pellet precipitate. The supernatant enters the clear water pool for reuse, and the lower sludge enters the sludge dewatering equipment (sludge pressure) Filter machine), mud cake for transportation.

Characteristics of sand washing wastewater

Sand washing wastewater treatment method

The treatment of sand washing wastewater is nothing more than the separation of mud and water, and the mud sand is separated by physical methods. Since the sand washing wastewater contains a large amount of sediment, the fine sand is first precipitated by the deep sediment purification body, and then the fine sand is precipitated. Control the solid content entering the dosing and flocculation step to achieve the purpose of reducing the cost of the drug, and then add the flocculant to form a pellet precipitate. The supernatant enters the clear water pool for reuse, and the lower sludge enters the sludge dewatering equipment (sludge pressure) Filter machine), mud cake for transportation.

Comments

Post a Comment